Our lab has changed quite a lot since this first build for the Shanghai Auto Show back in 2015. The footage here shows some of the work that is involved in preparing, planning, installing and testing the 5 major components of the FMS (full motion simulator). The main categories are:

1) Software – building the custom track, modeling the vehicle, recording custom sounds and make the software event friendly

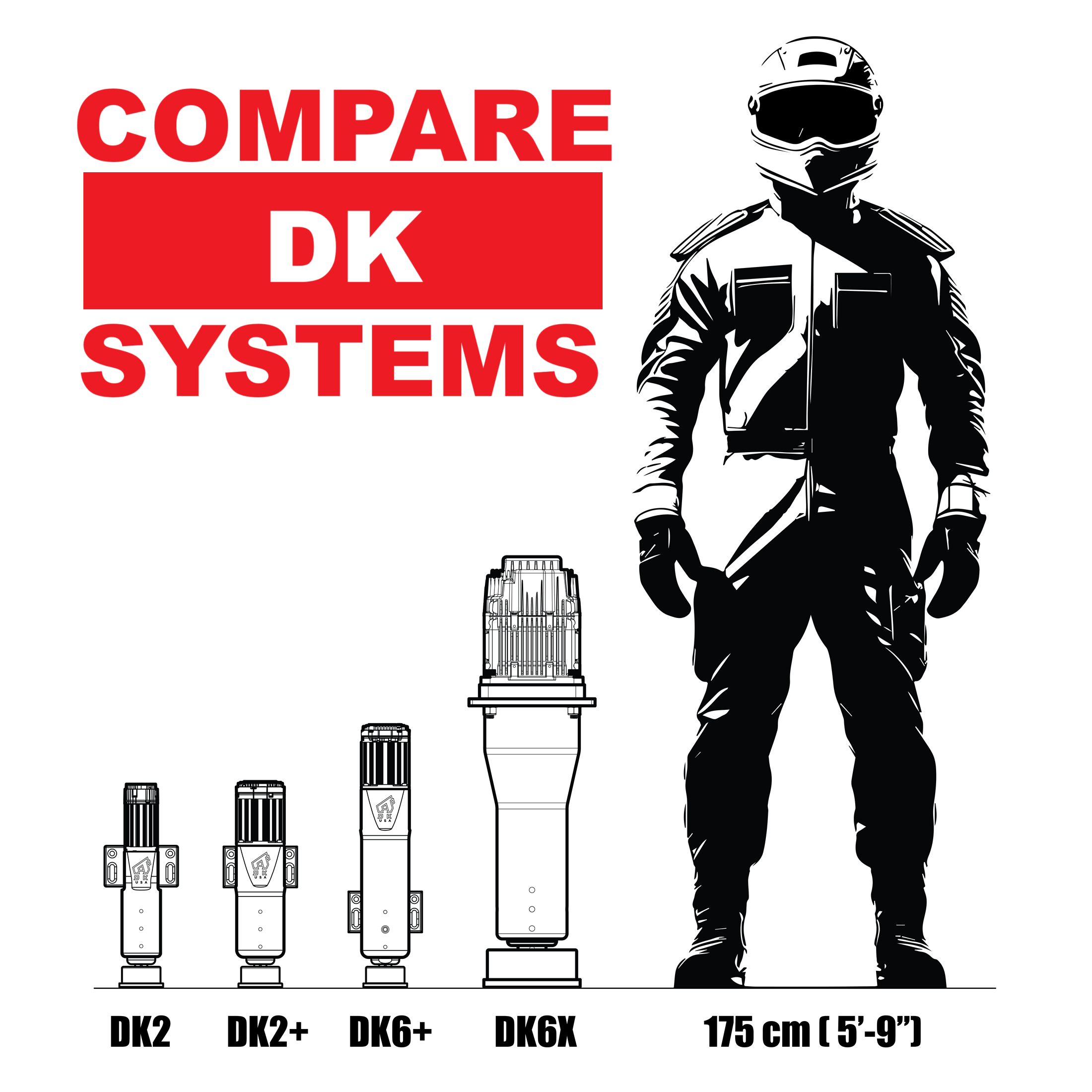

2) Motion – choosing, planning, fabricating the correction motion system with shipping mode options for car easy of transport in car haulers

3) Gauges – connecting directly to the vehicles CANBUS to gain access to the speed, rpm and disable and warning lights that may come up

4) Controls – connecting to and installing custom steering motors that connect directly to the steering wheel. Mechanical and electric locks are installed.

5) Displays and Sound: building the display, with exterior and interior speakers with redundant systems.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.